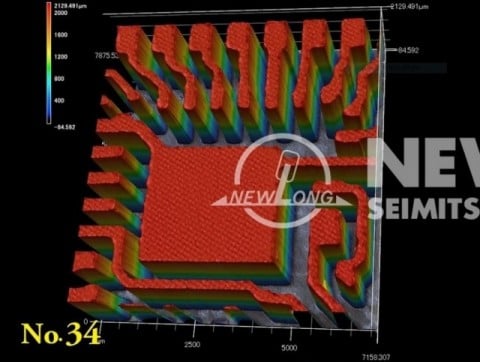

Screen printing for high aspect ratio

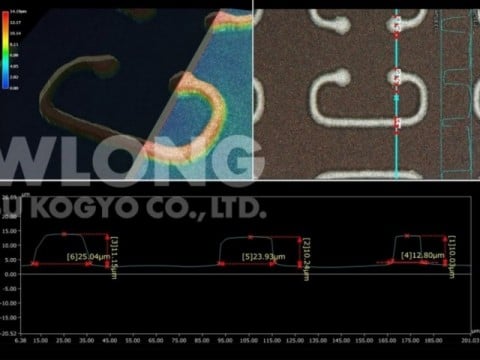

By optimizing the combination of vacuum screen printer, metal mask, and paste, we have achieved high aspect ratio pattern printing.

The table below shows previous line width and film thickness measurements using two different pastes.

(Unit: μm)

Solid matter (glass, silver, etc.) ink

| Non-solid (epoxy, etc. resin-based) ink

| ||

line width

| Film thickness

| line width

| Film thickness

|

45

| 14

| 500

| 130

|

55

| 18

| 800

| 200

|

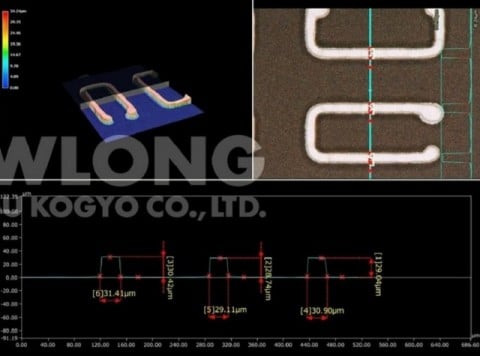

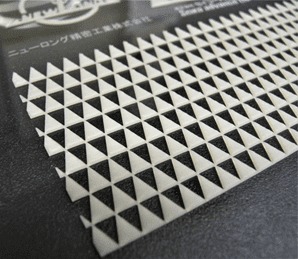

Currently, power semiconductors and power electronic components are required, and thick film printing with a high aspect ratio is required for various applications. We have achieved high aspect ratio pattern printing using a regular mesh plate under atmospheric conditions. Please take a look at our print samples using our unique technology that has been cultivated through repeated experiments.

(Unit: μm)

Solid matter (glass, silver, etc.) ink | Non-solid (epoxy, etc. resin-based) ink | ||

line width | Film thickness | line width | Film thickness |

10 | 10 | ||

30 | 30 | ||

220 | 180 | 200 | 100 |

250 | 200 | 250 | 150 |

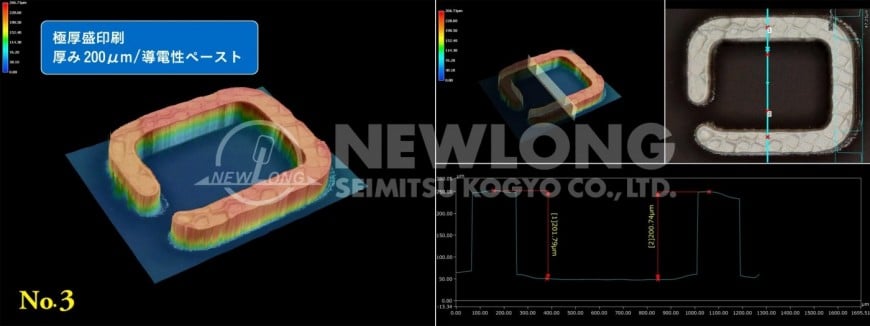

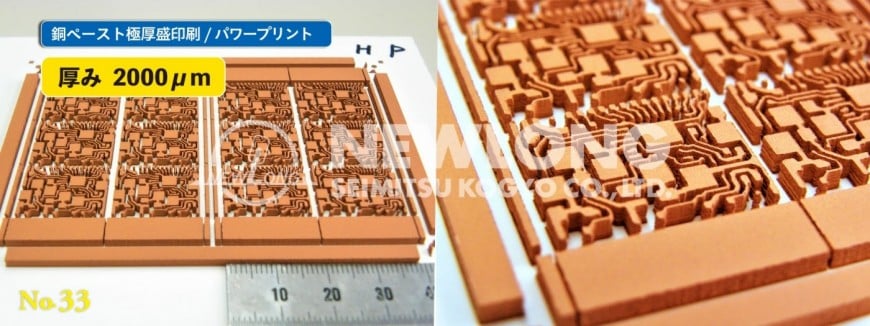

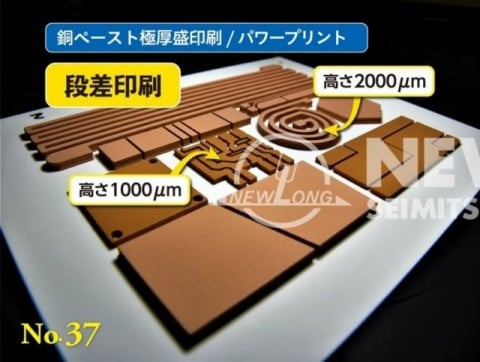

Our unique printing method (power print: patent pending) enables extremely thick printing.

It is also possible to print with steps on the printed matter.

(Unit: μm)

Our patent power print area | |||

Solid (glass, silver, etc.) ink | Non-solid (epoxy resin, etc.) ink | ||

Line width | film thickness | Line width | film thickness |

300 | 2000 | 250 | 1000 |

We are also challenging power printing (thickness) with resin paste.