~Although it is called printing pressure~

"Printing pressure" is an important condition in screen printing. It seems to refer to the pressure of the squeegee because the word "pressure" is attached, but it is more accurate to say that it is actually the force of the squeegee pushing the plate. There are two ways to apply this force: "down stop" (*1) and "air balance" (*1). The "downstop" flexes the Squeegee Rubber to give it more force. Therefore, the unit of "printing pressure" is expressed in terms of rubber deflection (mm). Although it is a force, the unit is mm, which is strange, but since the amount of deflection of the squeegee is proportional to the force, it is reproducible, so this is used for convenience.

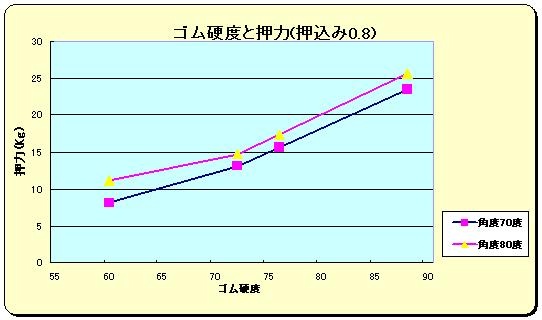

However, there is a caveat here. That's the hardness of Squeegee Rubber. How much the force changes due to the difference in rubber hardnessSB Major BM-01” was used to measure. (Figure 1)

You can see that the force is different even if the amount of deflection of the rubber is the same. Rubber hardness is important for "downstops".

"Air balance" adjusts the pushing force of the squeegee head of the printing press and gives it force. Since many printers use an air cylinder to drive the squeegee head, it is expressed as the air pressure (Mpa) supplied to this. Numerical control is possible compared to "Downstop". However, there is a caveat here.

The first is that the force varies even with the same air pressure (Mpa) because the standard of the air cylinder used by the printing machine is different. If the model of the printing machine is changed, it is necessary to check the standard of the air cylinder and reset the conditions.

The second is that the force per unit length changes when the length of the squeegee changes. It is necessary to adjust the air pressure (Mpa) according to the length of the squeegee.

The third is that the degree of deflection of the rubber changes due to air pressure, which changes the attack angle of the squeegee. Especially with a squeegee with a low hardness, if the air is raised, the rubber will buckle.

I get a lot of questions about which method is better, but the difference is in how to apply force, and there is no difference in applying force, so there is no big difference. I think that you should understand each feature well and choose the one that you think is easy to manage.

*1 ・・・ The name may differ depending on the printer manufacturer.

"SB Major BM-01Please contact our sales department for details onContact.