Last timeThe Subtle Relationship Between Printing Pressure and Film Thickness, I introduced that the deflection of the squeegee affects the film thickness (the thickness of the printed ink).

This deflection of the squeegee is essential for smooth ink extrusion and for avoiding damage to the plate.

However, it is also true that squeegee deflection can adversely affect high-definition printing.

This deflection of the squeegee is essential for smooth ink extrusion and for avoiding damage to the plate.

However, it is also true that squeegee deflection can adversely affect high-definition printing.

In particular, due to the clearance (gap between the plate and the workpiece) and the tension of the plate, the balance of the squeegee printing pressure differs between the center and the periphery of the plate, so the deflection of the squeegee changes depending on the location.

It's fine if you can apply enough printing pressure, but if you don't want to put stress on the workpiece, the effect is noticeable when you print with a very weak printing pressure.

Recently, there have been many cases where multiple products are cut out from a single workpiece, and this "printing results differ depending on the location" is a factor in lowering yields.

It's fine if you can apply enough printing pressure, but if you don't want to put stress on the workpiece, the effect is noticeable when you print with a very weak printing pressure.

Recently, there have been many cases where multiple products are cut out from a single workpiece, and this "printing results differ depending on the location" is a factor in lowering yields.

To solve this problem, we have developed a "special squeegee".

This time, we will use this special squeegee and compare the results of actual printing.

This time, we will use this special squeegee and compare the results of actual printing.

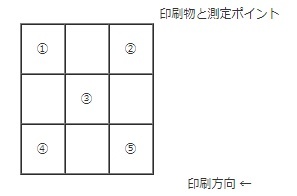

Lines of 150 μm in length and width were printed, out of 9 divided lines, 5 points of the variation in film thickness was measured.

The equipment, ink, plate and printing conditions are exactly the same, the only difference is the squeegee.

The equipment, ink, plate and printing conditions are exactly the same, the only difference is the squeegee.

010101010101

It's obvious when you look at the graph.

It can be seen that the special squeegee has much less variation in film thickness depending on the chamfering position than the flat squeegee.

It seems persistent, but the only different condition is the squeegee.

It can be seen that the special squeegee has much less variation in film thickness depending on the chamfering position than the flat squeegee.

It seems persistent, but the only different condition is the squeegee.

This special squeegee already has a proven track record in cutting-edge LCD seal printing (no light distribution film damage), etc., and is recognized by customers for its excellent characteristics.

If you usually suffer from poor yield due to multi-sided printing with weak printing pressure, why not try our special squeegee?

For details, please call our sales office or Click here for more information.Please contact us from the form.

We also assist our customers with in-house printing experiments.

Please feel free to contact us for more information.

For details, please call our sales office or Click here for more information.Please contact us from the form.

We also assist our customers with in-house printing experiments.

Please feel free to contact us for more information.

*These printing results are experimentally performed at our company, and may differ depending on the ink, plate, squeegee speed, pushing force, clearance, etc.